With the arrival of the apple harvest season, in the orchard, farmers are busy picking, basketing, handling, and then sent to the processing plant for cleaning and sorting packaging, an orderly process, a busy scene, everywhere overflowing with the joy of harvest.

Entering the factory, the apple intelligent sorting line is in operation, let's see how the processing is like.

Part 1: feeding

The feeding part can meet the large and small turnover baskets at the same time.

Part 2: spraying and air-drying

The spraying and natural air-drying area provides deeper cleaning and drying of surface water for apples.

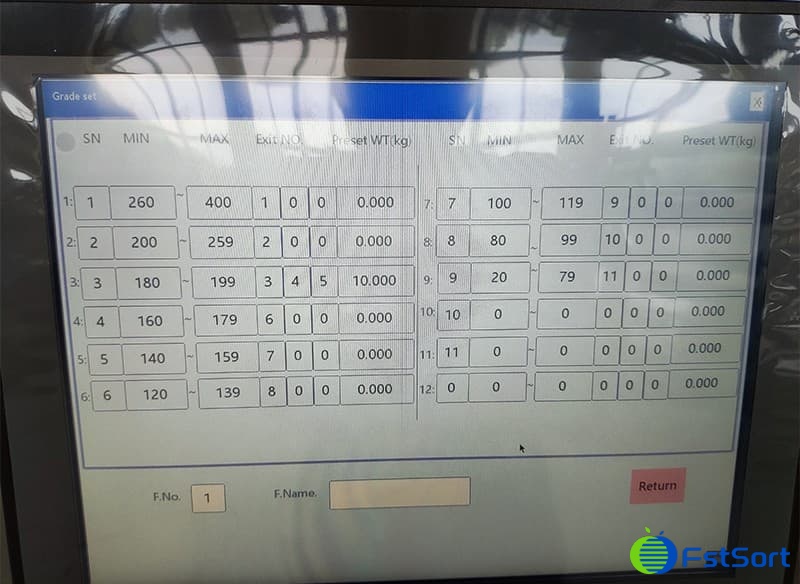

Part 3: Intelligent sorting

The intelligent apple sorting machine can classify apples under non-destructive conditions to better meet the market's requirements for high quality apples.

The intelligent apple sorter is put into use to improve the quality of the fruit, meet the needs of different consumers for graded apples, enable apples to sell at a good price, and increase the income of producers.

Part 4: Packing process

The unique optimization process of the manual or semi-automatic apple packing system allows for a better combination of the different apple sizes from the sorter, ensuring accurate and consistent weights, standardization and reduction of losses.

If you also want to know more about this intelligent sorting line, please feel free to contact us.